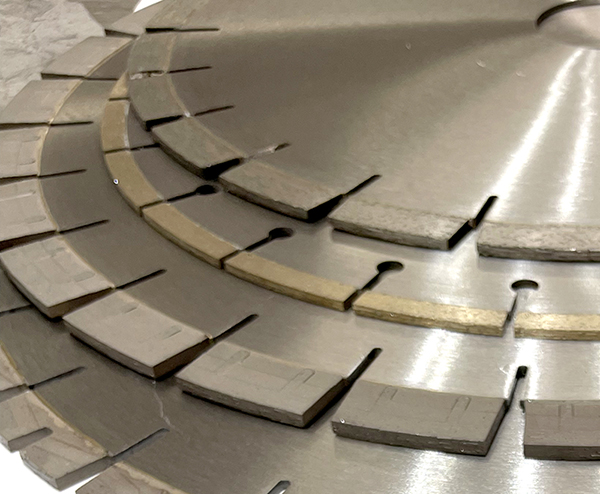

Diamond saw blade, a multi blade tool commonly used for cutting bridge aluminum, acrylic, and stone. In the entire history of metal cutting, the emergence of diamond saw blades has effectively compensated for many shortcomings of hard alloy saw blades and carbon steel saw blades.

Excellent cutting performance is an inherent advantage of diamond saw blades, and due to the use of harder and more heat-resistant diamond saw teeth, the lifespan of diamond saw blades is also very long.

Compared to ordinary hard alloy saw blades, the lifespan of diamond saw blades is often several months longer. Of course, there are many factors that affect the lifespan of diamond saw blades.

In addition to the quality of the saw blade itself, in the actual production process, the use of diamond saw blades and whether the operator's operation is standardized, as well as the depth and linear speed of the feed, will affect the service life of a diamond saw blade.

At present, there are four commonly used methods for manufacturing diamond saw blades, including cold pressing sintering method, hot pressing welding method, rolling method, and tooth embedding method.

Method 1: Cold pressing sintering method

The diameter of diamond saw blades manufactured by cold pressing sintering method is generally below 400 millimeters due to limited manufacturing technology.

Meanwhile, the cold pressing sintering method has the advantage of low production cost, especially for some wet saw blades. In the manufacturing process, the cold pressing welding method is generally used.

The diamond saw blade using this manufacturing process often ensures stable operation when cutting difficult profiles such as granite, mixed hard soil, asphalt, etc.

Method 2: Hot press welding method

For enterprises producing diamond saw blades, in order to ensure stable production, they often choose hot press welding method at present.

This method of manufacturing diamond saw blades is currently the most popular method. Meanwhile, compared to the cold pressing welding method, this manufacturing method can produce diamond saw blades with a larger diameter.

The diameter range is generally between 350 millimeters and 2200 millimeters, and some giant diamond saw blades, such as those used to cut stones, use this process in the manufacturing process. The basic manufacturing procedures include mixing, hot pressing sintering, arc grinding, welding, and cutting.

Method 3: Rolling method

Diamond saw blades manufactured by rolling method have relatively low manufacturing cost, and diamond saw blades produced by this manufacturing process are generally used for sawing materials such as clocks, gemstones, bearings, etc.

The diamond saw blade manufactured using this method is generally made of sheet metal, with a diameter between 80-120 millimeters and a thickness between 0.2-0.4 millimeters.

Method 4: Gear Insertion Method

As the name suggests, the inlay method is to embed diamond sawteeth on the tooth seat of the saw blade substrate. The diamond saw blade produced by this manufacturing process is thinner, with the sawteeth appearing discontinuous in the outer circle and firmly embedded in the wheel rim. The cutting is sharp and the chips are easy to remove.

At the same time, the advantages of using this manufacturing process for saw blades are high cutting efficiency, low material loss, and the ability to cut thinner materials. This is because in addition to the stone field, saw blades manufactured using this process are also used in the aluminum profile processing field.

At present, regardless of the manufacturing method used, it can effectively ensure the quality of diamond saw blades and cut profiles. When it comes to aluminum profiles, due to the advanced manufacturing process, the cutting performance of the saw blade is quite excellent.

In addition, due to the excellent metal cutting characteristics of diamond saw blades, they can be repeatedly ground a lot.

Compared to ordinary hard alloy saw blades that can only be polished 1-2 times in a lifetime, diamond saw blades can be polished 6-8 times in a lifetime. For enterprises, it means adopting a grinding method, which can save a large amount of cost expenses.

Post time: Dec-14-2023