1、 What is a diamond circular saw blade

Diamond circular saw blade is a commonly used cutting tool, which is a saw blade with a diamond cutting edge located on the inner or outer circumference of the saw blade. It is widely used in the processing of hard and brittle materials such as stones and ceramics. The diamond saw blade mainly consists of two parts: the substrate and the blade. The substrate is the main supporting part of the adhesive blade, while the blade is the cutting part that starts during use. The blade will continuously consume during use, while the substrate will not. Diamond particles are wrapped in metal inside the cutting head, which plays a cutting role in friction cutting of the processed object during the machining process. During use, the metal matrix and diamond are consumed together. It is generally ideal for the metal matrix to consume faster than diamond, which ensures both the sharpness of the cutting head and the service life of the cutting head.

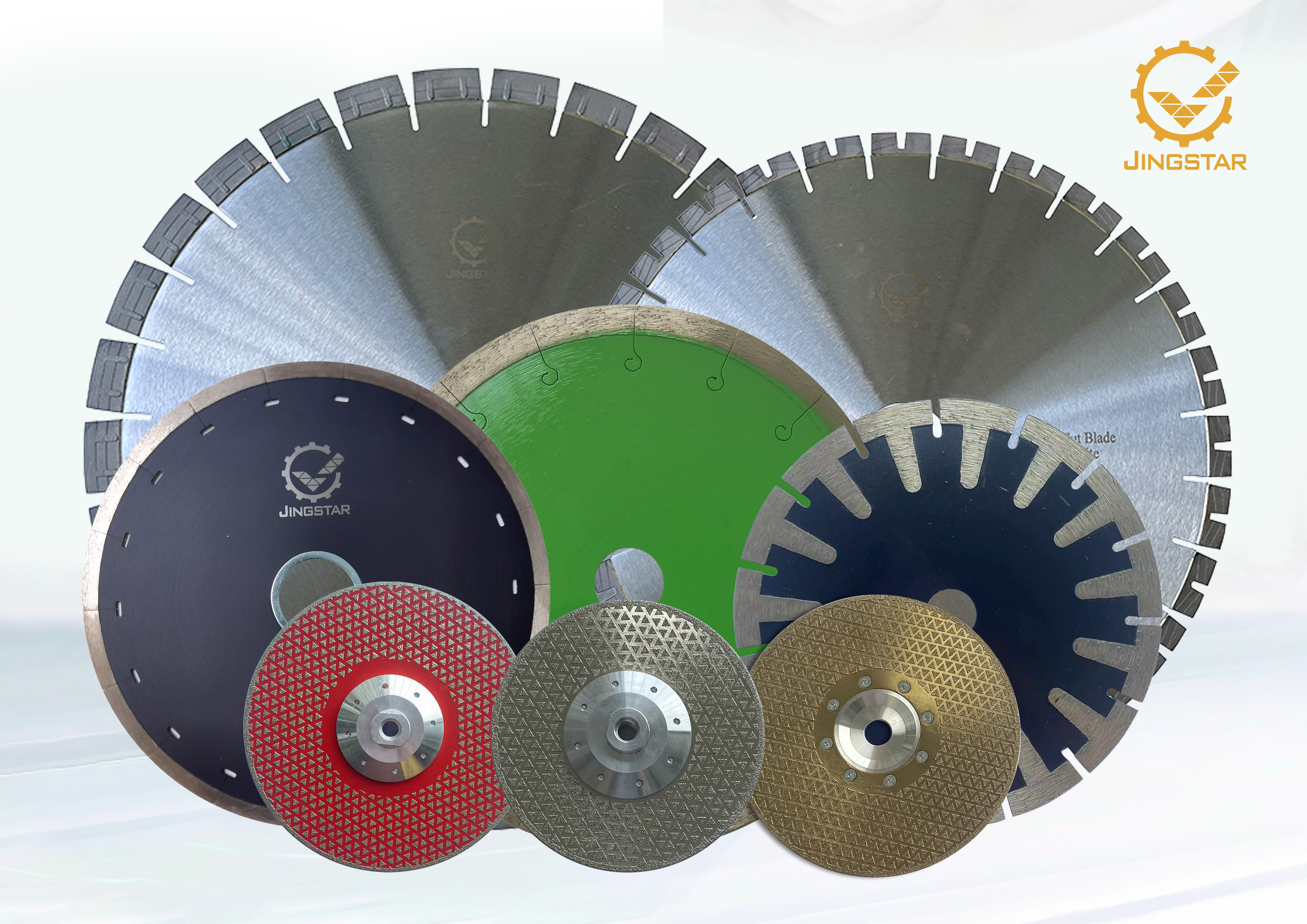

The diameter span of diamond circular saw blades is large, with carving blades of several millimeters and large saw blades of several meters in diameter. There are also many cutting objects, and the structure, hardness, and size of the cutting objects vary greatly. Therefore, their processing and manufacturing methods, raw materials used, and usage requirements are all different.

2、 Classification of diamond circular saw blades

Diamond circular saw blade is currently the most commonly used sawing tool in China's stone industry, which is generally circular in shape. It uses methods such as powder metallurgy or electroplating to embed diamond particles around the substrate. Utilizing the high strength and hardness of diamond particles to shear and crush other materials for cutting purposes. There are many types of diamond circular saw blades and their classification is also very complex. There are usually several classification methods:

1. Classification by manufacturing process:

(1) Sintered diamond saw blade

There are two types of sintering: cold press sintering and hot press sintering.

(2) Welding diamond saw blade

There are two kinds of brazing and Laser beam welding. Brazing is to weld the cutter head and the substrate together through high temperature melting medium, such as high-frequency induction brazing saw blade, vacuum brazing saw blade, etc; Laser welding uses high temperature laser beam to melt the cutting head and the contact edge of the substrate to form metallurgical bonding.

(3) Electroplated diamond saw blade

It is the process of attaching the blade powder to the substrate through electroplating. However, due to severe pollution, the country is gradually abolishing this electroplating method.

2. Classification by processing object:

Marble cutting saw blade, granite cutting saw blade, concrete cutting saw blade, etc.

3. Classification by appearance:

Continuous edge saw blades, blade type saw blades, turbine type saw blades, etc. Of course, the above classification method cannot include all diamond circular saw blades, and there are also many special purpose diamond circular saw blades. Select different types of diamond saw blades for processing different materials.

3、 The main characteristics of diamond circular saw blade cutting

Circular saw blade cutting has the advantages of convenient operation, high efficiency, and good processing quality. But the noise is loud and the blade rigidity is poor. During the cutting process, the saw blade is prone to vibration and deviation, resulting in poor parallelism of the workpiece being cut.

4、 Factors affecting the efficiency and lifespan of diamond circular saw blades

The factors that affect the efficiency and lifespan of diamond circular saw blades include cutting process parameters, diamond grade, particle size, concentration, and bond hardness.

1. Sawing parameters

(1) Saw cutting speed

In practical work, the linear speed of diamond circular saw blades is limited by equipment conditions, saw blade quality, and the properties of the stone being sawn. In terms of the service life and cutting efficiency of the saw blade, the linear speed of the saw blade should be selected based on the properties of different stones.

(2) Sawing depth

Within the allowable range of saw machine performance and tool strength, larger cutting depths should be selected as much as possible to improve cutting efficiency. When there are requirements for the machined surface, small depth cutting should be used.

(3) Feed speed

The feed speed is the feed speed of the stone being sawn. Its value should be selected based on the properties of the sawn stone. Generally speaking, sawing softer stones, such as marble, can increase the sawing depth and reduce the feed speed, which is more conducive to improving the sawing rate. Sawing fine-grained and relatively homogeneous granite can increase the feed speed appropriately. If the feed speed is too low, the diamond blade is easily ground flat. However, when sawing granite with coarse grain structure and uneven hardness, the cutting speed should be reduced, otherwise it will cause the saw blade to vibrate and cause diamond fragmentation, thereby reducing the cutting rate.

2. Diamond particle size

The commonly used diamond particle size ranges from 30/35 to 60/80 mesh. The harder the rock, the finer the particle size should be chosen. Because under the same pressure conditions, the finer the diamond, the sharper it becomes, which is beneficial for cutting into hard rocks. In addition, generally large diameter saw blades require high cutting efficiency, and coarser particle sizes such as 30/40 mesh and 40/50 mesh should be selected; Small diameter saw blades have low cutting efficiency and require smooth rock cutting sections. It is advisable to choose finer particle sizes, such as 50/60 mesh and 60/80 mesh.

3. Diamond concentration

Diamond concentration refers to the density of diamond distribution in the working layer matrix. According to regulations, the concentration of 4.4 carats of diamond per cubic centimeter of working layer matrix is 100%, and the concentration of 3.3 carats of diamond is 75%. The volume concentration represents the volume of diamond in the block and specifies that the concentration is 100% when the volume of diamond accounts for 1/4 of the total volume. Increasing the concentration of diamond is expected to extend the lifespan of the saw blade, as increasing the concentration reduces the average cutting force per diamond. But increasing the concentration will inevitably increase the cost of the saw blade, so there is a most economical concentration that increases with the increase of sawing efficiency.

4. Hardness of cutter head binder:

Generally speaking, the higher the hardness of the bond, the stronger its wear resistance. Therefore, when sawing rocks with high abrasiveness, the hardness of the binder is easily high; When sawing soft rocks, the hardness of the binder should be low; When sawing rocks with high abrasiveness and hardness, the hardness of the binder should be moderate.

5、 The Development Trend of Diamond Circular Saw Blades

Diamond circular saw blades are the main tools in the stone processing industry. In recent years, the number of artificial diamonds used in the stone processing industry has risen sharply, and the application of diamond circular saw blades is also increasing. Overall, the development of diamond circular saw blades both domestically and internationally has the following characteristics: producing efficient and high-quality saw blades, and developing saw blade grade specialized diamonds; Pay more attention to the research of powder, matrix, and sintering process; Pay more attention to the research on the sawability and sawing mechanism of stone materials; Laser welding saw blade has been developed; Develop oversized diamond circular saw blades. At present, the application of diamond circular saw blades is becoming increasingly widespread. In the future, the development direction of diamond circular saw blades is to improve cutting efficiency, saw blade life, reduce production costs, and also achieve environmental protection.

Reference: "Diamond and Diamond Tools Knowledge Q&A" by Zhang Shaohe and Hu Yule

Post time: Aug-04-2023