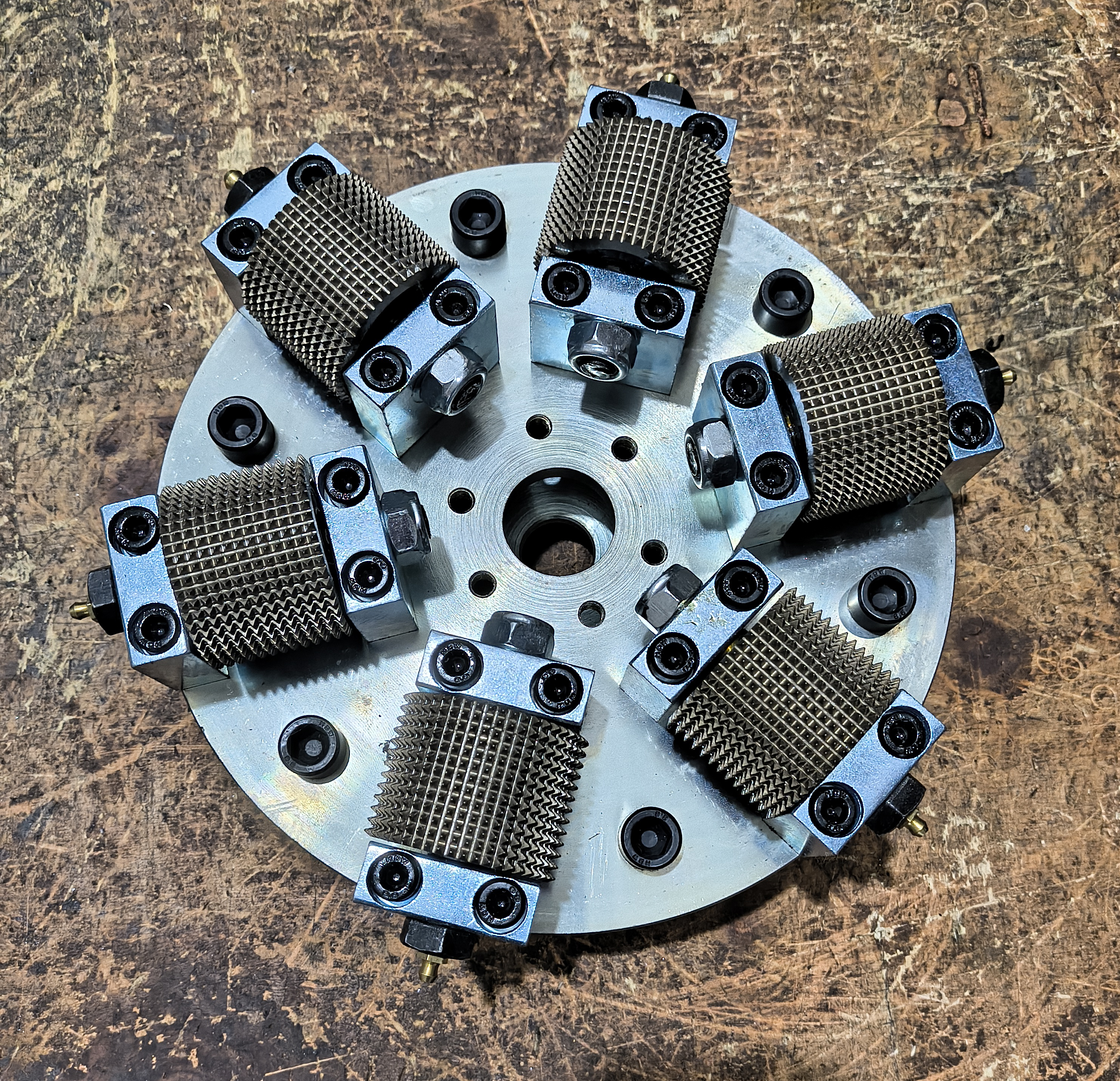

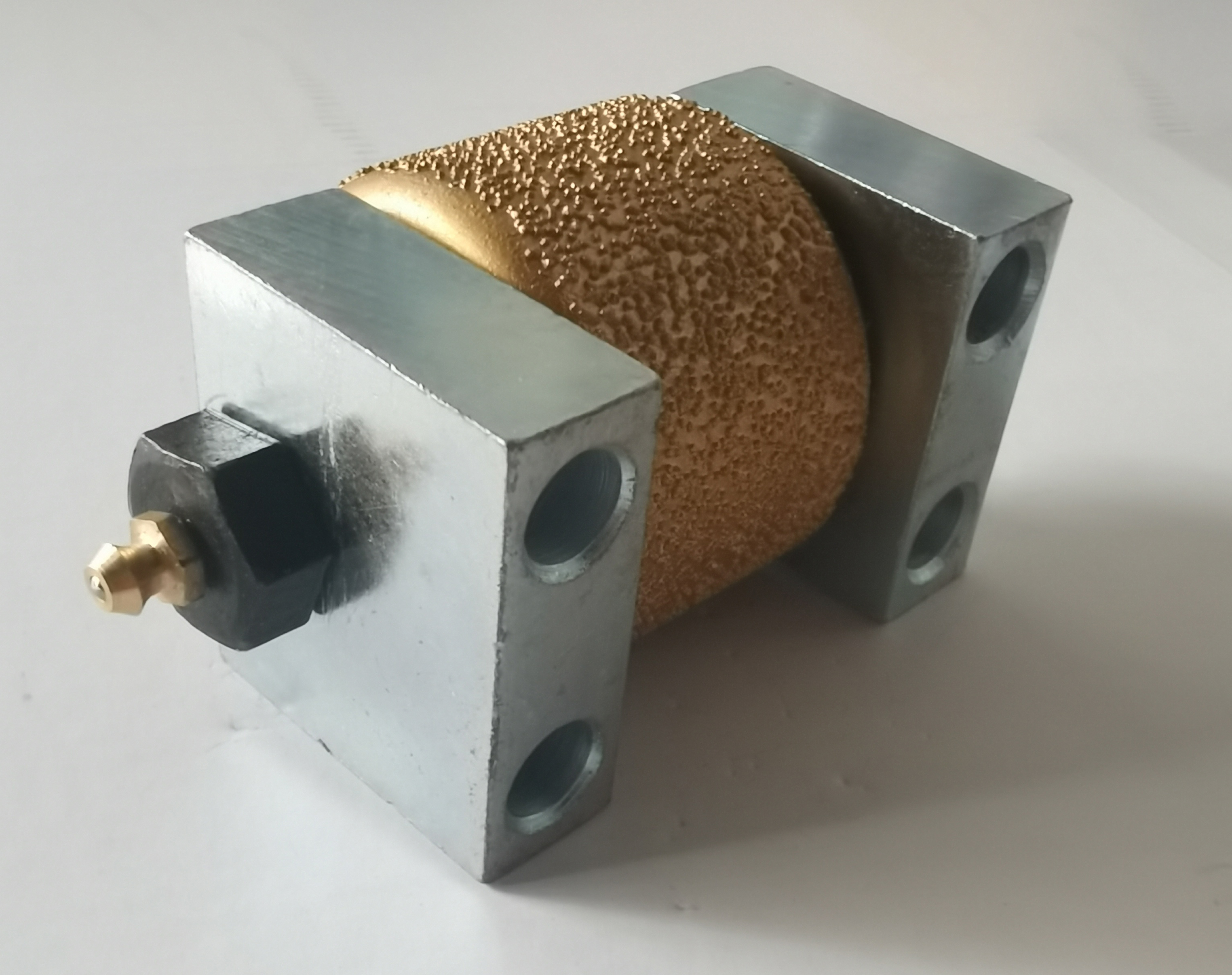

Bush hammer is an important tool in the stone processing industry, mainly used for rough grinding, fine grinding, and polishing of materials such as marble, granite, and artificial stone. Its surface pattern is similar to lychee peel, with strong grinding force, good heat dissipation, and long service life. According to different processing requirements, bush hammer can be classified according to binder, particle size, purpose, and shape.

1. Classified by binder

-Metal bonding agent bush hammer: made by sintering copper, cobalt, nickel and other metal powders, with high hardness and strong wear resistance, suitable for rough grinding and shaping of hard stones such as granite and quartz, with high processing efficiency but rough surface.

-Resin bonded bush hammer: using phenolic resin or polyimide resin as the bonding agent, it has good elasticity and is not easy to scratch the stone during grinding. It is suitable for fine polishing and matte treatment of soft stone such as marble and limestone.

-Mixed binder bush hammer: combining the advantages of metal and resin, balancing wear resistance and polishing effect, suitable for semi precision processing of medium to high hardness stone materials.

2. Classified by Diamond Grain Size

-Coarse grain size (20/30~60/80 mesh): used for rough grinding and rapid material removal of stone, such as preliminary shaping after cutting of raw materials.

-Medium particle size (80/100~200/300 mesh): Used for semi precision machining, eliminating rough grinding marks and improving surface flatness.

-Fine grained (325 mesh and above): Used for fine polishing to achieve a matte or mirror finish on the surface of the stone.

3. Classified by processing purpose

-Flat grinding wheel: used for surface grinding of large stone slabs, such as the processing of floors and countertops.

-Corner grinding wheel: specifically designed for chamfering, rounding, and polishing stone edges to prevent chipping.

-Irregular grinding wheel: suitable for processing complex curved surfaces such as carving and lines.

4. Classified by shape and structure

-Flat grinding wheel: Standard flat grinding, suitable for large-area machining.

-Cup shaped grinding wheel: used for edge processing or small area high-precision grinding.

-Fan shaped grinding wheel: suitable for stone joint treatment and local repair.

Bush hammers are widely used in stone processing, and selecting the appropriate type can significantly improve processing efficiency and surface quality. Metal binders are suitable for rough grinding of hard stone, resin binders are suitable for polishing of soft stone, and particle size selection directly affects processing accuracy. In the future, with the development of ultrafine diamonds and new binders, the performance of bush hammer will be further improved to meet higher requirements for stone processing.

Post time: Jul-15-2025